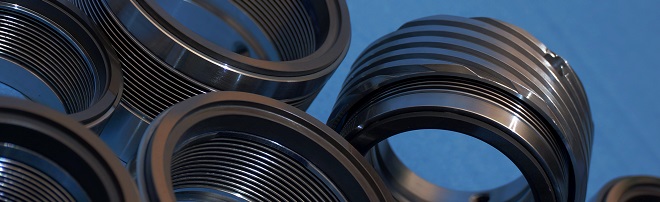

Manufacture Mechanical Seal Products

We produce various mechnical seals and components for pumps, mixers and agitators.

Component seals are usually more attractive in pricing, but the installation costs more.

Cartridge seals are popular because they are generally much easier to install.

Mechanical seal solution is greatly affected by the system within which it is installed.

So clear specification of the working environment is very important for us to propose an appropriate

solution for clients. Even when the clients have their solution and mechnical drawing already,

we encourage the clients to share with us more information about the system when possible.

It actually happened more than once that our engineering team pointed out

possible issues of the original mechnical drawing we received from the clients, discussed with them

and received very positive feedback. All this work is to ensure that we have the appropriate material

and design before we start production.

Once we have seal specification and mechanical drawing, we follow proprietary procedures based on years of

experience throughout the production. We use raw material of high quality, mostly acquired from United State.

They are crafted into parts with precision. Depending on the types of seals, we have multiple quality checkpoint

among various stage of the production. After the final assembly, they are also put through air tight test

as specified in API 682: when testing at 1.7 bar (25 Psi) the pressure drop cannot exceed 0.14 bar (2 PSI)

in five minutes.