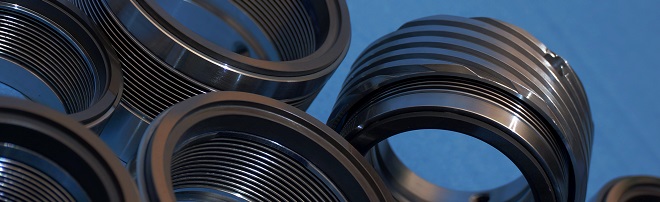

Welded Metal Bellow Seals

Welded metal bellow mechanical seals are often the choice for systems with extreme temperature conditions

and / or corrosive products. They are often not the first choices for operations with very high pressure.

That being said, when it is required, high pressure operating environment is often coped with by utilizing double-ply metal bellow components.

For secondary seal, either elastomer O-ring or flexible graphite is used depending on the types of the seal. Usually for

high temperatures (>400oF or >250oC), flexible graphite is preferred for its better

performance with such environment. Our welded bellow components can be provided along or within in different cartridge seal arrangements.

Many of our clients / partners are mostly interested in the metal bellow components. You are welcome to use our

cross reference page to identify our replacement

components for some well known brands.

We design and manufacture welded metal bellows components made of Inconel 718, AM350,

17-4 PH, Hastelloy C276, Titanium, etc. Usually, for low to medium temperature range, our clients would use 17-4 PH or HC-276 metal bellows.

For high temperatures, Inconel 718 is often the preferred choice. There are operating environments where a full Titanium (TA2) metal bellow component is required.

We also normally recommend Inconel 718 metal bellow components for cryogenic environment.

Depending on the material chosen and the specific design, We have manufactured

welded metal bellows with shaft size up to 267 mm (10.50 in, for PTA application).

Welded metal bellows usually provides longer service time for the seal because it has less moving parts

and usually have lower seal face wear rate. We are proud of our expertise in the manufacturing of

welded metal bellow seals.

If you are interested in these products, please do not hesitate to

contact us for more detail.