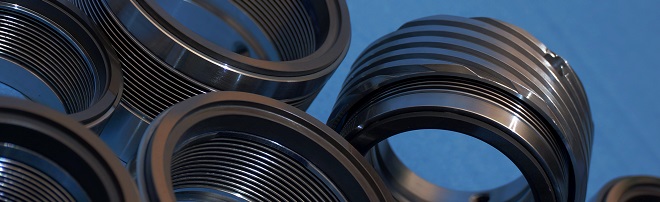

Single / Dual Cartridge Seals

Cartridge Seals are pre-assembed mechanical seals that are usually easier to install.

Having the components pre-assembled into a package not only means faster installation,

it also reduces the chance of human error during installation of the seal. That is one main reason

why cartridge seals are getting more popular when the budget and the system allows.

If the product being sealed is gas or liquid that is toxic, hazardous, or corrosives, it is likely that

a dual cartridge seal is needed (API 682 arrangement 2 and 3). A dual cartridge seal very often is formed

with tandem configuration (face-to-back), or face-to-face configuration.

In a tandem configuration, the outer seal essentially works as backup

for the primary seal. If the primary seal failed, and the product leaked into the buffer zone (between two seals)

and raised some alarm, the backup seal can still hold it until the engineering team can fix the issue.

In a face-to-face arrangment, if the liquid or gas between the two seals has higher pressure compared with the sealed product

(API 682 arrangement 3), it effectively creates a barrier. When any issue happens with the inner seal (closer to the product),

the barrier material flows into the product instead of the other way. If the liquid or gas between the

two seals has lower pressure compared with the sealed product (arrangement 2), it serves as a buffer, and the outer seal serves

as a backup of the inner seal.