|

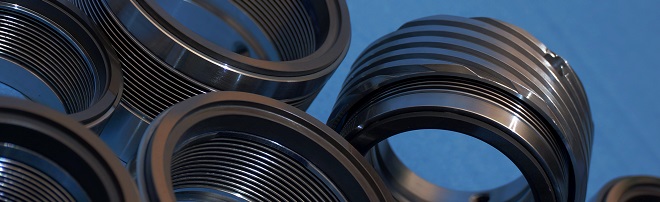

Specialize in various WELDED METAL BELLOW SEALS and COMPONENTS.

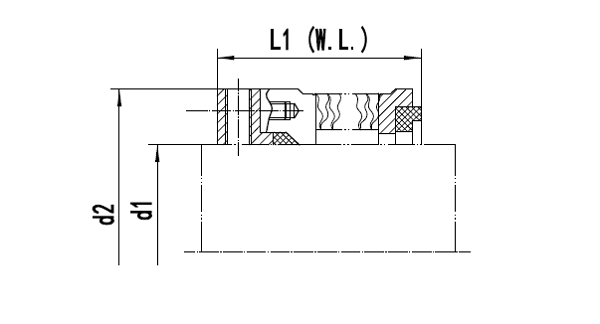

Cartridge seals SIMPLIFY INSTALLATION.

Double cartridge seals INCREASE system RELIABILITY.

Various products applied to HIGH SPEED, EXTREME TEMPERATURE, HIGH PRESSURE environments.

|